Solar panels are susceptible to substantial wear and tear during their lifecycle. Faults are more likely to occur when the solar farm has just become operational (manufacturing defects, incorrect installation, wrong cabling) or a few years after, due to prolonged exposure to the elements, poor cleaning, and usage.

Keeping the health status of the solar farm in check and doing regular maintenance is key to preventing mild issues from becoming more severe and therefore requiring drastic countermeasures. One single anomaly on a solar cell can affect the performance of the entire solar panel or even a full string of solar panels. However, most faulty panels don’t show any sign of malfunctioning until it is too late, if at all.

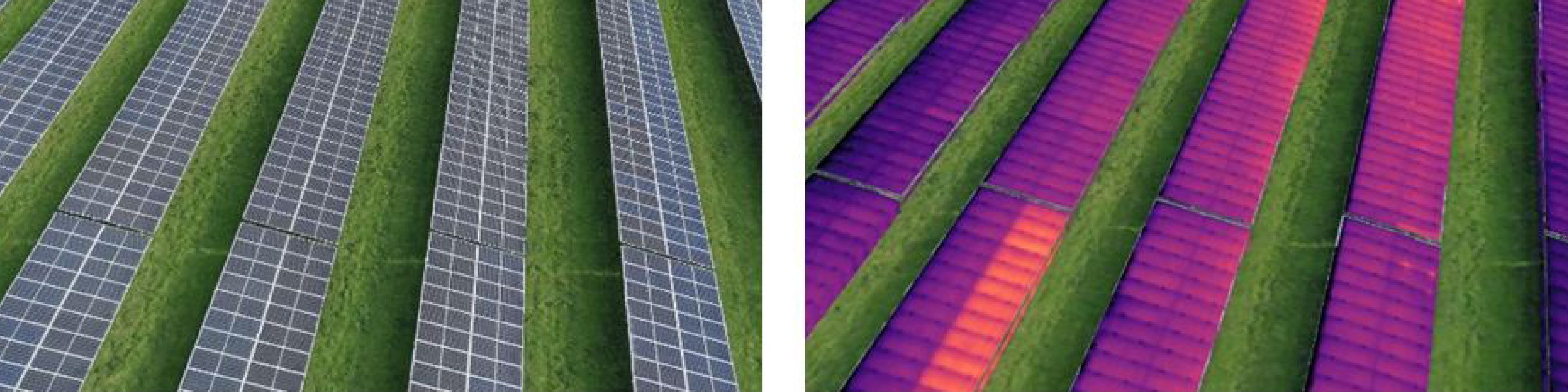

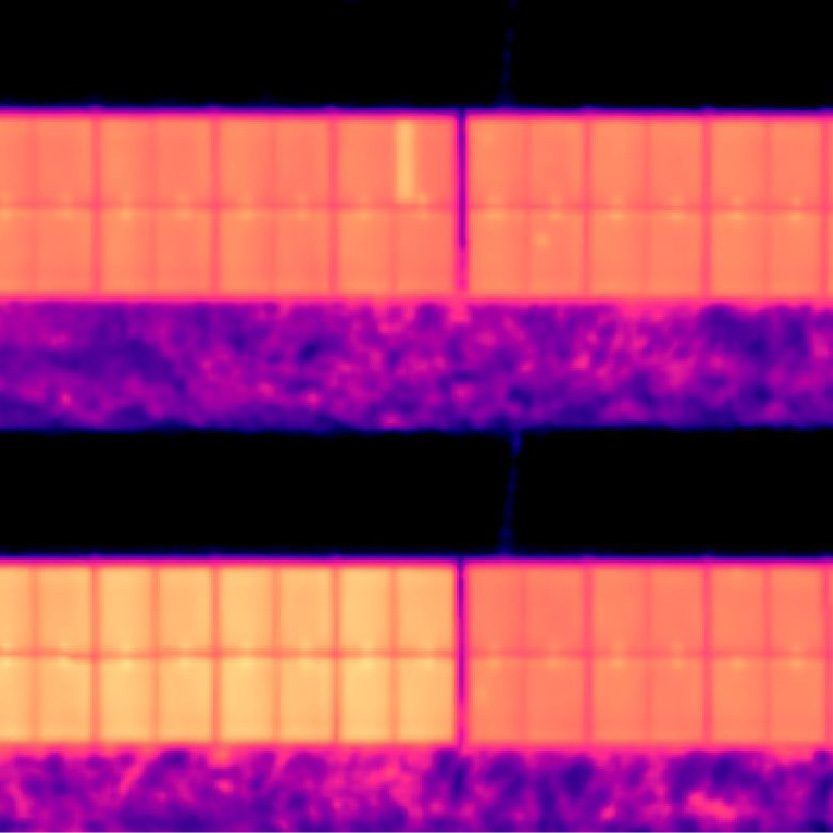

That’s where thermography comes into play. When radiation from the sun is absorbed but not fully converted into electricity due to any ongoing defect, the faulty component of the solar panel heats up. The temperature spike can be read by thermal sensors up to years in advance before the defect eventually shows visual symptoms. Thermography helps detect issues that may reduce energy yield and ultimately revenue over a long period if not spotted and repaired otherwise.

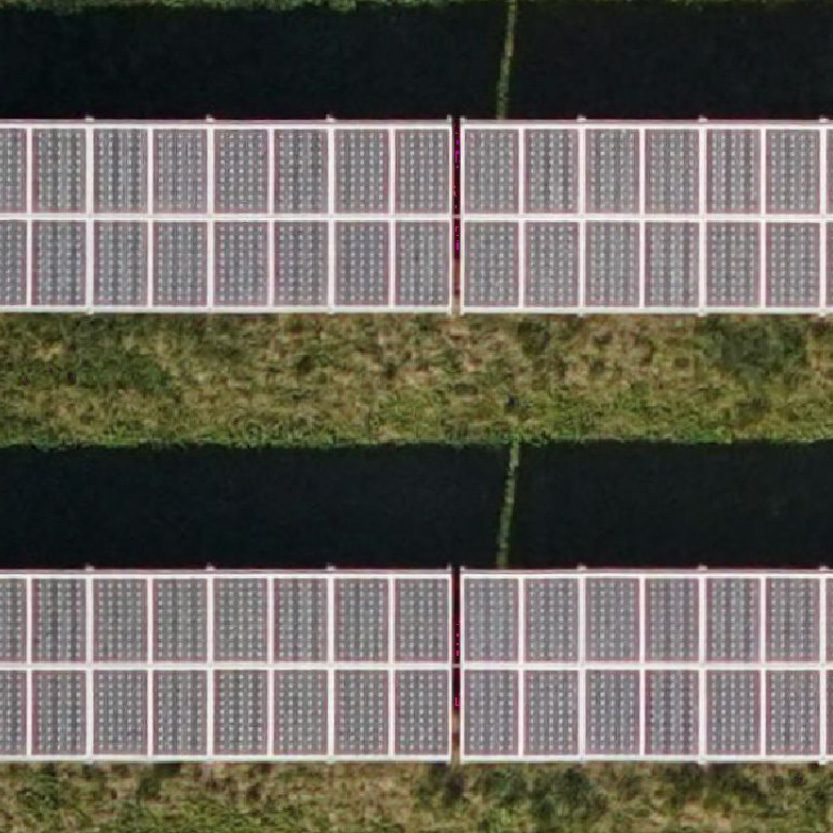

Our dedicated Drone Survey team has launched a new service that drastically improves on traditional, manual thermography. We carry out solar farm inspections with drones mounted with multiple sensors, including high-resolution and thermal infrared cameras, to capture many layers of information in a fraction of the time.

Compared to manual thermography, drone inspections are several times faster. MKO can inspect up to 15MW a day, which would require approximately two weeks for traditional ground surveys. That makes inspections less expensive and also grants a higher degree of data consistency across the solar farm – as weather conditions may change from day to day.

Drones are more accurate as well. Our Drones include units mounted with Real Time Kinetic (RTK) modules, enabling a centimetre-level accuracy when it comes to GPS positioning and georeferencing. Coupled with a high-resolution camera and top-edge thermal camera, our remote sensing experts will detect even the slightest anomaly and will be able to point at the exact solar panel and location coordinates with confidence.

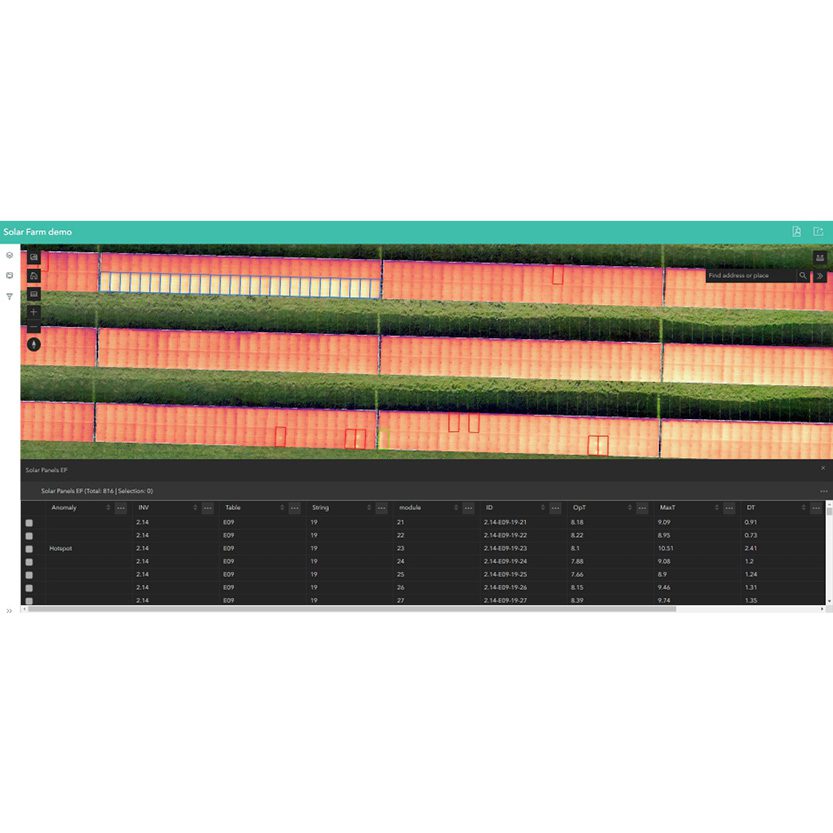

Where manual thermography can produce a PDF report at best, aerial imagery can be the input for all different kinds of digital products. After each inspection, we generate and deliver a full Web Map Portal which includes 2D and 3D Digital Twin of the solar farm with interactive tools, a statistical dashboard with analytics and insights, and a web viewer to look at layouts, drawings and documents from anywhere.

For more information, contact our team info@mkoireland.ie