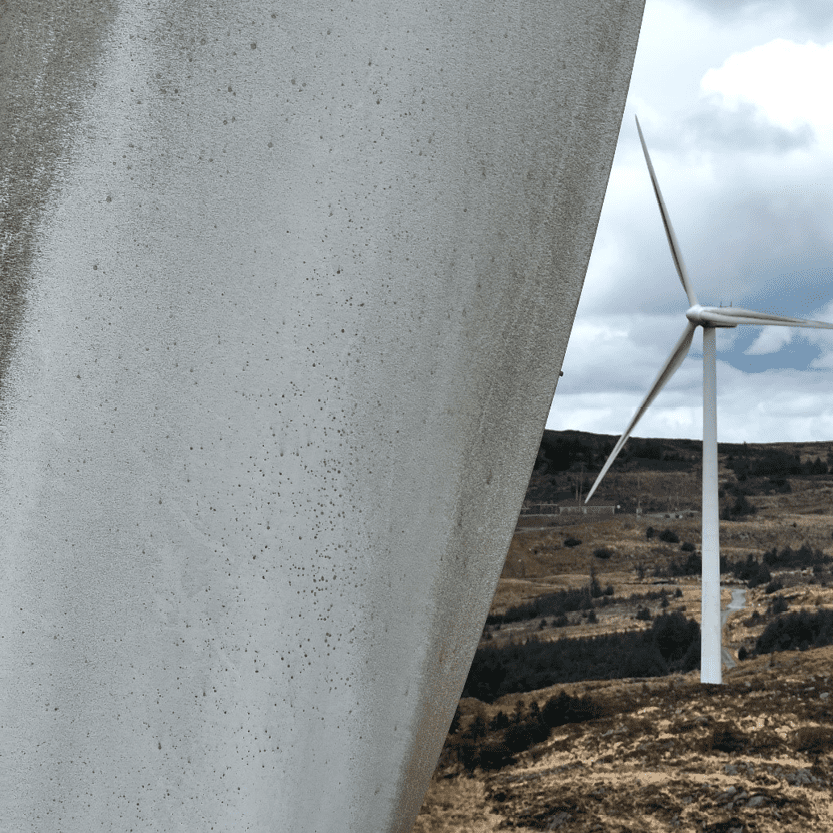

Wind turbines are exposed to the elements and over time they can be susceptible to degradation, particularly in the wet and windy uplands in the west of Ireland. Early identification of faults on wind turbines is key for optimising their performance and planning maintenance activities, ultimately preventing any potential issues or defects from getting worse over time.

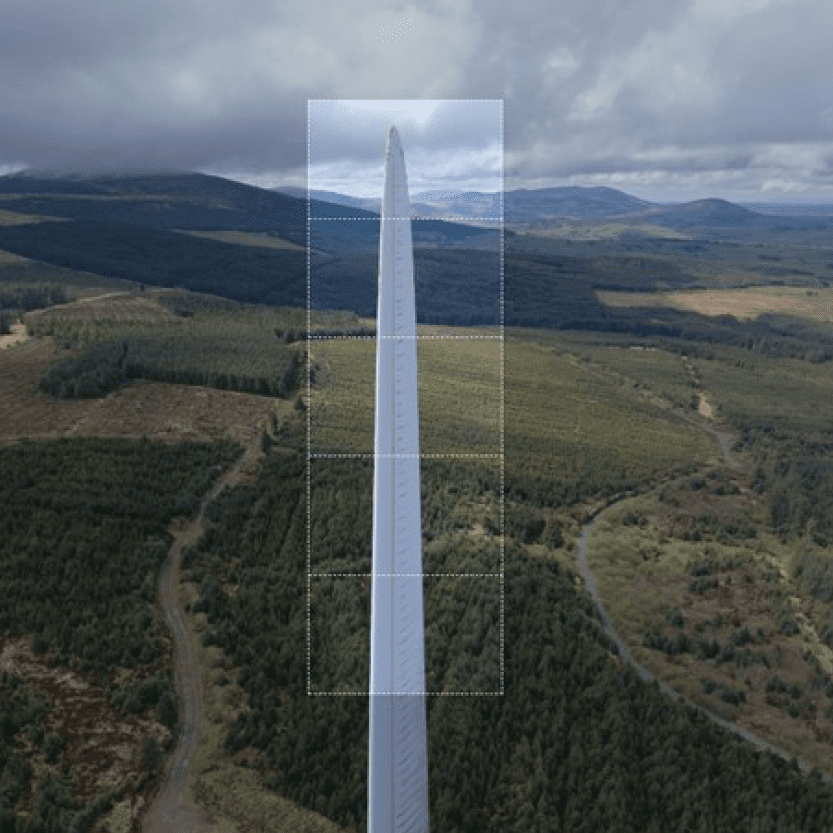

The use of drones for the inspection of wind turbines has become a well-established method for informing the precise requirements of turbine maintenance. Manual surveys (exterior inspection using ropes and harnesses) are often time consuming, high risk and have the potential to be inconsistent. Whereas, the use of a drone equipped with a microscopic zoom camera can be a safe and timely alternative to manual methods, complete with a catalogue of detailed photographic data which can be shared and analysed with multiple stakeholders.

Our remote pilots have used drones to conduct turbine inspections for several wind farms in Co. Kerry and Co. Cork. Our drone was put to the test at the start of the year as we set out to complete a series of time-critical inspections in weather conditions which were occasionally quite challenging. We were delighted with the performance of our drone in the wind and rain. Our team can now average inspection of approximately six turbines per day. This is therefore an efficient process, limiting the downtime of turbines compared to other inspection methods.

During our latest inspections, we were able to charge the drone’s batteries directly from the turbine tower, using 100% renewable energy.

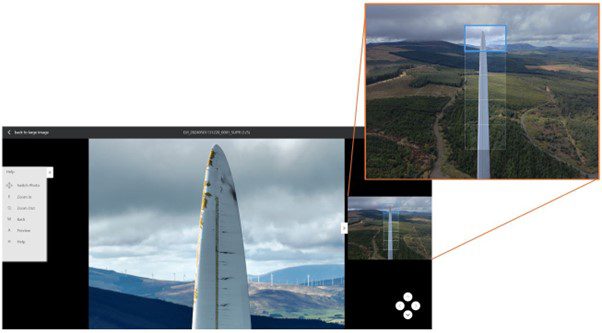

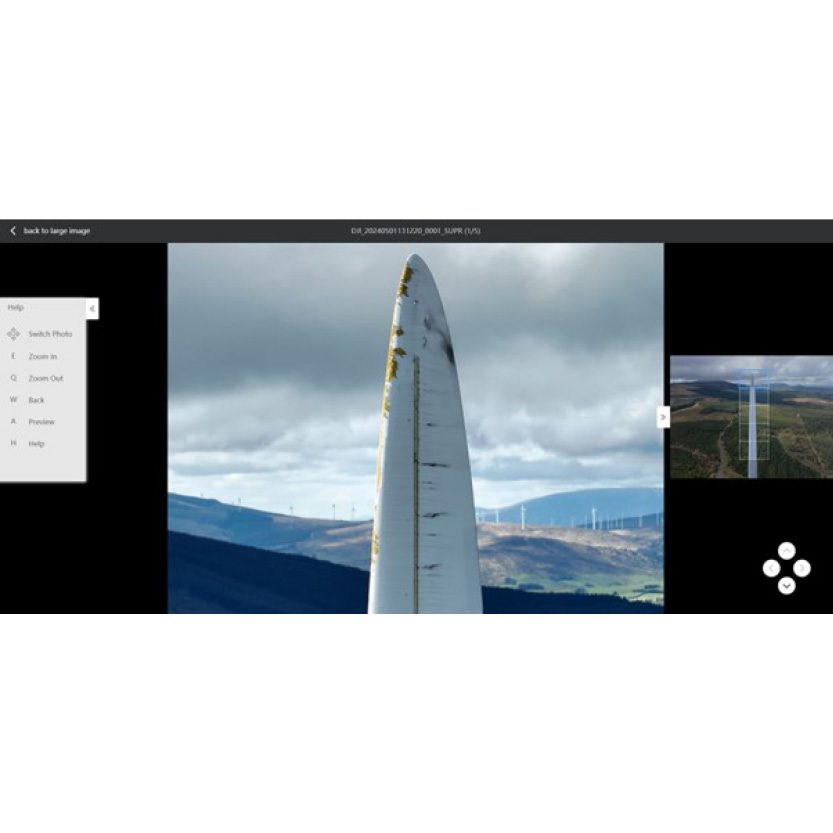

The blade inspection data is analysed and sent off to maintenance crews who can effectively scope, schedule and implement maintenance works for a particular wind farm. In addition to traditional reports, MKO has made the photographic imagery from the inspections available to be visualised within an intuitive and interactive browser viewer application which includes the following benefits:

- The application enables the user to quickly scroll through the high-resolution photos whilst keeping track of where the camera is focused on the blade.

- It speeds up the process of identifying and assessing the faults during the report generation.

- The survey data can be uploaded to the applications and delivered within 24 hours of the flight so that our clients can get an immediate sense of the health status of each turbine.

- Any issues or defects later identified and reported in the blade assessment report pdf can be easily double-checked and analysed in detail.

If you want to know more about our wind blade inspections and what else MKO Drone Service can offer, read our digital brochure here or contact us at info@mkoireland.ie